|

|

Follows the theoretical assessment of the forces arising during the impact of a car front end with the rear end of a truck equipped with a rigid underride guard.

Centered impact

Assumptions:

- both vehicles are traveling in the same straight trajectory;

- the impact is essentially plastic;

- no lateral displacement of the vehicles occurs after the impact;

- after the impact both vehicles remain in contact as a single mass (m1 + m2) at speed v3.

From the conservation of momentum:

- m1 v1 + m2

v2 = (m1 + m2) v3

(1)

- v3 = (m1 v1

+ m2 v2)/ (m1 + m2)

(2)

where:

- m1 = mass of the truck (kg)

m2 = mass of the car (kg)

v1 = velocity of the truck before impact (m/s)

v2 = velocity of the car before impact (m/s)

v3 = velocity of both vehicles after impact (m/s)

Before impact, the kinetic energy

of the vehicles is:

E0 = 0.5(m1 v12 + m2 v22) (3)

And after impact:

E1 = 0.5(m1 + m2)v32 (4)

where:

- En = kinetic energy (J)

The energy lost during impact is:

(5)

(5)

Taking the closing velocity va

= (v1 + v2), we obtain:

(6)

(6)

The work done by the average force

arising during the collision in crushing the car is:

F.s = D E = E1 – E2 (7)

where:

- F = average force acting during the

impact (N)

s = car crush (m)

and

(8)

(8)

Substituting eq. (8) in eq. (6),

we obtain the average force acting between the vehicles during the impact:

(9)

(9)

Eq. (9) shows that the average force

acting during the impact is function of the truck and car masses, closing

speed and car crush distance (considering a rigid guard).

In order to verify the influence of the truck mass in the force acting during the impact, let us take three different kinds of cars ("small", "medium" and "large"). For each category we will consider two models, one produced in Brazil and one produced abroad. Crushing data for Brazilian models were obtained from a Brazilian industry which asked us not to divulge the names of its models. Crushing data for the foreign models were obtained at the NHTSA (National Highway Traffic Safety Administration) web site [2].

Table I presents the data employed to calculate the forces (crush distance for centered impact against rigid flat barrier).

|

|

|

|

|

|

|

|

|

(48 km/h) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(50 km/h) |

|

|

|

|

|

|

|

|

|

Table II shows the average force acting during impact calculated according eq. (9):

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table II presents the average dynamic impact loads acting during the impact. Experimental results obtained by BEERMANN [3] show that the ratio of quasistatic crush loads to dynamic mean axial buckling loads for closed-hat section members (similar to front structural members of cars) ranges from 1.30 to 1.56 (average value = 1.40), with no influence of the speed within 30 to 50 km/h. Dividing the values of Table II by 1.40 we obtain the corresponding quasistatic crush loads that can be used for design purposes. These quasistatic loads are presented in Table III.

TABLE III

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

According to the data presented in Table III, an underride guard able to resist an impact at 50 km/h of a hypothetical average car should be designed to resist the following quasistatic loads at the drop arm level (P2):

|

|

|

|

|

|

|

|

|

|

|

|

Offset impact

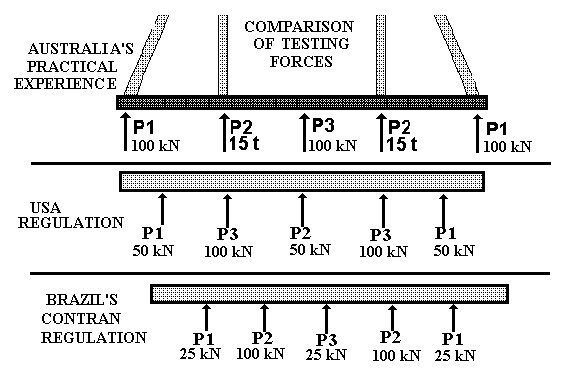

Unfortunately we were not able so far to get the crush data necessary to assess the force acting during an offset collision. So the assessment of these force will be based on the experimental results obtained by RECHNITZER et al. [4] e MARIOLANI et al. [5], who designed underride guards according to the quasistatic strength requirements proposed by BEERMANN [3], that is, 150 kN at the drop arm level (P2) and 100 kN at the center of the main beam (P3) and 300 mm from the outermost parts of the vehicle (P1).Both underride guard were successfully tested at 50 km/h, what allows one to suppose that the ratio of 1.5 between the load at the drop arm level and the load at the center of the beam and near its outermost part is satisfactory.

Based on this ratio (1.5) we suggest that underride guards should satisfy the following quasistatic strength requirements to be able to resist the impact of an AVERAGE car at 50 km/h:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example of "half safety"

Comparing the guard strength suggested above with the test forces required by the new American and the Brazilian (= European) standards, we can easily conclude that the traffic authorities do not know what a collision means...

References

- RECHNITZER, G. – "Design Principles for Underride Guards and Crash Test Results". Notes for SAE Heavy Vehicle Underride Protection TOPTEC, April 15-16 1997, Palm Springs, USA.

- NHTSA (National Highway Traffic Safety Administration) Vehicle Crash Test Data Base. URL: http://www-nrd.nhtsa.dot.gov/database/nrd-11/veh_db.html

- BEERMANN, H.J. – "Behaviour of Passenger Cars on Impact with Underride Guards". Int. J. of Vehicle Design, vol. 5, nos. 1/2, pp. 86-103, 1984.

- RECHNITZER, G.; SCOTT, G. & MURRAY, N.W. – "The Reduction of Injuries to Car Occupants in Rear End Impacts with Heavy Vehicles". SAE Paper 933123. 37th Stapp Car Crash Conference Proceedings, San Antonio, Texas, USA, November 8-10, 1993.

- MARIOLANI, J.R.L.; ARRUDA, A.C.F; SANTOS, P.S.P; MAZARIN, J.C. & STELLUTE, J.C. – "Design and Test of an Articulated Rear Guard Able to Prevent Car Underride". SAE Paper 973106. VI International Mobility Technology Conference and Exhibit, São Paulo, Brasil, October 27-29, 1997.