|

|

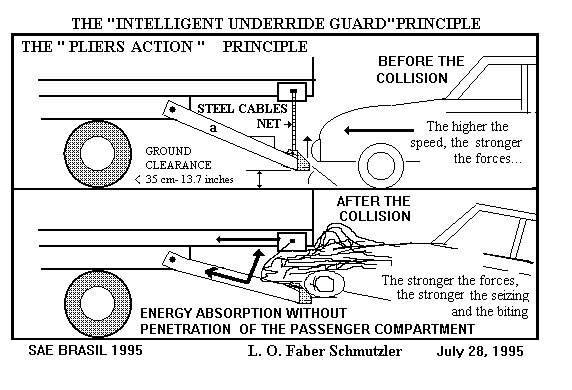

(A BRAZILIAN PROPOSAL FOR SAVING LIVES)

|

The basic idea is to definitively avoid car intrusion under the truck bed. This project also assures the upwards movement of the guard, in the case that ground obstacles are hit, and facilitates ground clearance adjustment, in the case of large differences in height by loading/unloading.Forces liberated by the collision will easily lift the car (unlike the conventional underride guard that lifts the truck), avoiding penetration of the car under the truck. This may be the main characteristic of this kind of structure/guard.

As a consequence, this intrusion of the passenger compartment by the truck bed will not occur, which is the basis of the objective.GUARD FEATURES

- Height from the ground: 215 mm (8.46 inches)

- Mounted flush with the rear end of the truck bed

- Design loads:

- P1 = P3 = 150 kN

- P2 = 200 kN

IN THE CASE OF EXCESSIVE SPEED AND BREAKING OF THE STEEL CABLES, THE CAR WILL CONTINUE TO BE PRESSED BETWEEN THE CARGO TRAY AND THE GUARD SUPPORT AND NEVER UNDER THE CARGO TRAY.

THIS PROJECT WAS SUCCESSFULLY TESTED ON APRIL 14, 1998 AT THE GENERAL MOTORS CRASH LABORATORY FACILITIES NEAR THE CITY OF INDAIATUBA IN THE STATE OF SÃO PAULO. THE CAR WAS A VECTRA IN A 50% OFF CENTER COLLISION AT A SPEED OF 40 MPH (64 KM/H).

PERFORMANCE EVALUATION

THE WINDSHIELD WAS NOT TOUCHED BY ANY PART OF THE TRUCK, THEREFORE REMAINING INTACT AS DID THE PANEL. THE FRONT DOORS COULD BE EASILY OPENED, WHAT WOULD FACILITATE THE EXIT OF THE PASSENGERS!

THIS MEANS THAT THE MAIN TARGET

WAS FULLY ACHIEVED:

ZERO PASSENGER COMPARTMENT INTRUSION!

THE FRONT BUMPER WAS THE FIRST PART OF THE CAR TO HIT THE STEEL CABLES, WHICH ASSURED THAT ALL ADVANTAGES OF THE CAR'S OWN ENERGY ABSORPTION CAPABILITIES WERE REALLY EMPLOYED, TO THE BENEFIT OF THE PASSENGERS´ SAFETY.

It became clear that the same prototype could resist higher impact speeds and forces. Therefore, this design should be optimized and improved for higher duties.E-MAILALL DETAILS CAN BE FOUND IN SAE TECHNICAL PAPER 982879